Project Description

Objectives:

Develop advanced simulations technology to account for temperature increase and adaptive control systems to adjust the machine settings during the start-up of the production line.

M2i FEA simulation work:

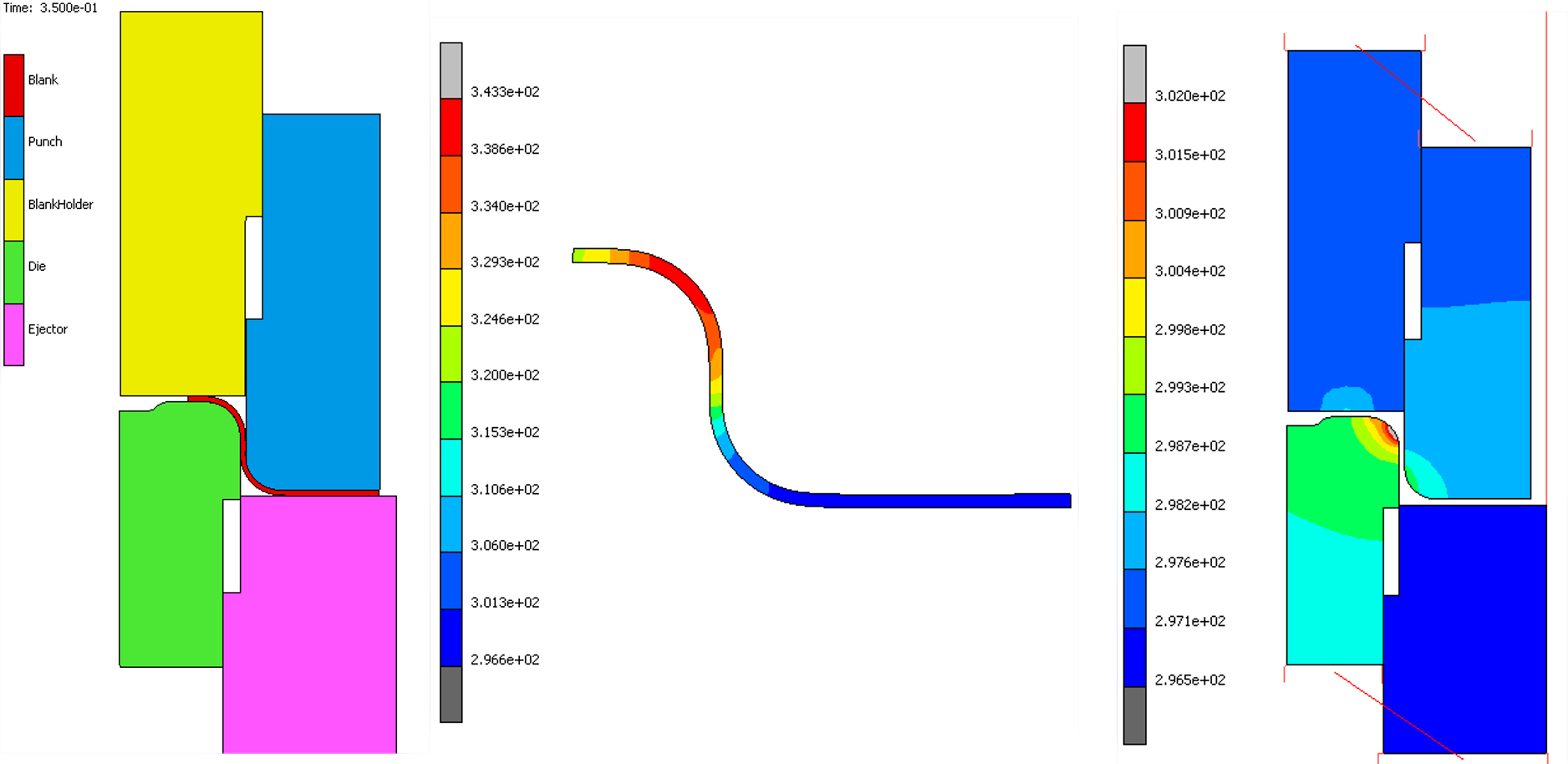

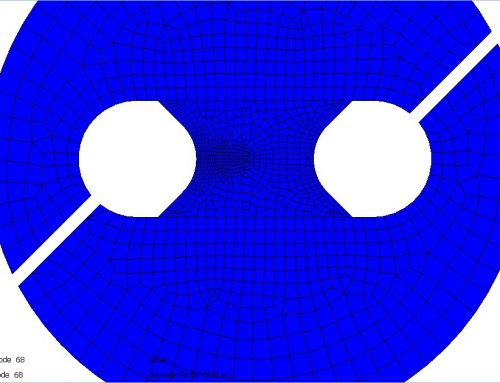

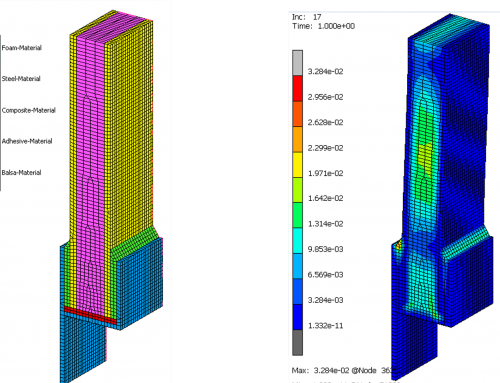

- Implement a tribology based friction law in the commercial FEA software MARC

- Simulation and validation of the thermo-mechanical behaviour of the deep-drawing tools in consumer goods production line

- Reduction of computational time by using an extrapolation method

Industrial Benefits:

- Reduce the computational time by 50%

- Increased the accuracy of simulations, compared with deep-drawing with constant friction coefficient.

- Reduce the number of experiments, the waste and time to market

Contact persons M2i

News

Looking back at a successful Final ASPECT Event

Last week, on 15 June 2021, the Final ASPECT Event took place as an online event. The ASPECT project ran for five years and was funded from the INTERREG North-West

Teaser ASPECT; Register now for the Final event

On 15 June 2021, the final event of the INTERREG project ASPECT will mark the end of the project. Watch the teaser and register for the event.

Practical Training “Temperature-induced friction influence in sheet metal forming processes”

We are happy to invite you to a Practical Training in ‘temperature-induced friction influence in sheet metal forming processes’, which will take place on the 18th of June 2021 online

Register now for the ASPECT Final event

On 15 June 2021, the final event of the INTERREG project ASPECT will mark the end of the project. ASPECT has enabled the prediction and control of temperature-induced effects on

Final event ASPECT at ESAFORM 2020

From 4 to 6 May 2020, the ESAFORM Conference was organised for the first time as on-line conference. In its frame, the ASPECT consortium held a mini-symposium “Tribology in Sheet

Conference on Material Forming ESAFORM 2020

The 23rd International Conference on Material Forming ESAFORM 2020 will take place virtually on 4th-6th May 2020