Project Description

Key information

Program title: Circular Circuits

Project in the Spotlight: N21006

Funding: Perspectief P20-13

Market: Electronics, Supply chain management

Written by M2i Program Manager: Yulia Fischer

Project Description

The project will develop a fully circular generation of electronics. It will develop solutions to overcome technical, economic and societal bottlenecks for lifetime extension, reuse, repair, refurbishment and recycling through development of a new generation of electronic components, product-service design, new business models and advanced recycling technology. The project will make a pivotal contribution to the Dutch Government program ‘Netherlands Circular by 2050’, particularly for consumer goods and the manufacturing industry which are two of the five priority transition sectors.

Introduction

The challenges that Europe is facing regarding scarcity of resources, pollution and emissions have increased the pressure on society to put more emphasis on sustainable development and makes us look into the core of the economic process, co-creating value and sharing value across participants in the value chain. This is particularly challenging, because many examples of innovations required for securing renewable energy, environmental protection, resource efficiency and sustainability have failed to develop well-defined and successful business models (Tukker and Tischner 2010; Jonker et al. 2021).

To make circularity more concrete topic, WP5 of the Circular Circuits project (CC project) works on developing new business models for electronics domain. Our research investigates Circular Business Models (CBM) from an innovation ecosystem perspective with an embedded case study of the Dutch microelectronics industry. By exploring CBMs throughout the value chain from manufacturers to recyclers, and drivers/barriers towards circularity, we proposed suggestions on circular ecosystemic collaboration for both industry and policymakers.

Approach and results

To answer our research questions, we have opted for an embedded single-case study focusing on the Dutch microelectronics industry. This sector faces challenges in global competitiveness while transitioning to a circular product-service ecosystem. Data collection unfolds in two phases, utilizing multiple data units such as company visits, reports, discussions, interviews, and project meetings. This approach enables us to triangulate our findings and provide a holistic view of the ecosystem simultaneously.

The first phase encompassed 13 company visits, which included multiple project meetings, eight unstructured interviews with experts from various companies, an examination of sustainability reports and documentation provided by the companies, and observations.

These observations were partly documented through field pictures capturing factories, assembly lines, and products. Insights gleaned from observations, documentation, and interview data in the first phase prompted the formulation of more specific research questions. This, in turn, led to the development of an interview protocol and coding schemes for the second phase of our study on Circular Business Models (CBMs).

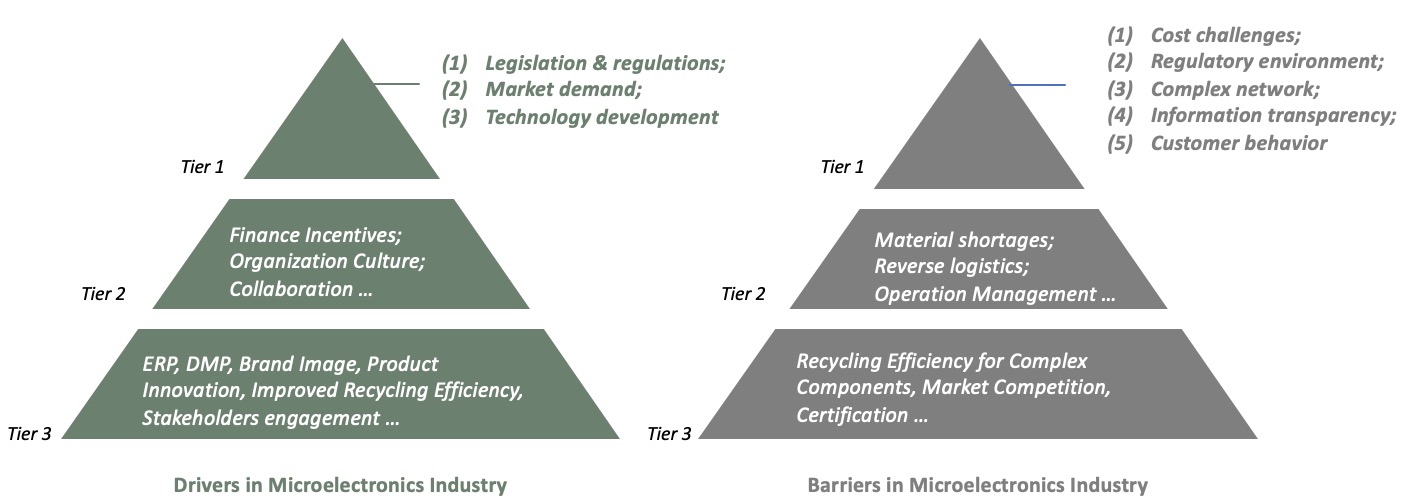

Figure 1. Driver and Barriers in microelectronics industry.

Our study reveals that companies employ diverse strategies to align with market demand, regulatory compliance, and technological advancements and face challenges due to cost constraints, and supply chain complexities. This delicate balance between environmental sustainability and economic viability underscores the complexity of circular practices.

Unique factors, such as extended producer responsibility and financial incentives, play roles in driving circularity. Collaborative efforts, information transparency, and balancing the triad of demand, supply, and production emerge as critical themes shaping the circular economy landscape. Overall, these companies navigate complexities, demonstrating a commitment to circular practices and sustainable development.

While this study has provided valuable insights into CBM innovation within the microelectronics industry, it also opens avenues for future research in the broader electronics sector. Several key areas warrant further investigation to advance our understanding of CBM and its applicability. Furthermore, future research can explore the development of new CBMs to optimise the economic, social, and environmental benefits of the electronics circular economy, contributing to both theoretical knowledge and practical application. For more information read our recent publication.

Industrial use cases

Two industrial use cases with the partners of the CC consortium have been successfully elaborated in the framework of the master thesis projects at Erasmus University. Koen Dittrich, Stef Lemmens and a PhD student Meihui Jiang supervised this work.

In2Waste Solutions use case

From January to June in 2024, student Amy van Baalen worked with In2Waste to investigate the circular business model for reusing legacy PCB components in the WEEE recycling industry. She identified key enablers and challenges, such as technological advancements and legislative pressures, and created a business canvas and RASCI operational flow for implementing the model. Interviews with experts from Circular Circuits consortium highlighted strong connections within the CC community, and Amy’s work has laid the basis for further exploration of the circular business model. Her thesis is here available.

“It was really helpful to have Amy investigate the circular business model for reuse. We learned a lot, and she assisted us with scientific implementation methods we might not have used otherwise.” Quote by Barend Ubbink from In2Waste Solutions. The photo shows the team: Barend Ubbink, Amy van Baalen and Meihui Jiang.

“It was really helpful to have Amy investigate the circular business model for reuse. We learned a lot, and she assisted us with scientific implementation methods we might not have used otherwise.” Quote by Barend Ubbink from In2Waste Solutions. The photo shows the team: Barend Ubbink, Amy van Baalen and Meihui Jiang.

Nedap use case

Student Catelijn van der Meer went to Nedap from February to June in 2024 to explore the possibility of the leasing model with a specific case of Nedap’s product ID POS 2, identifying internal and external factors critical to success, such as stakeholder collaboration, lifecycle management, reverse logistics, centralized support, and predictable costs. Furthermore, business partners’ contributions and refurbishing can be the future development direction. The exploration of a new circular business model will be continued after Catelijn’s initiatives. The thesis is here available.