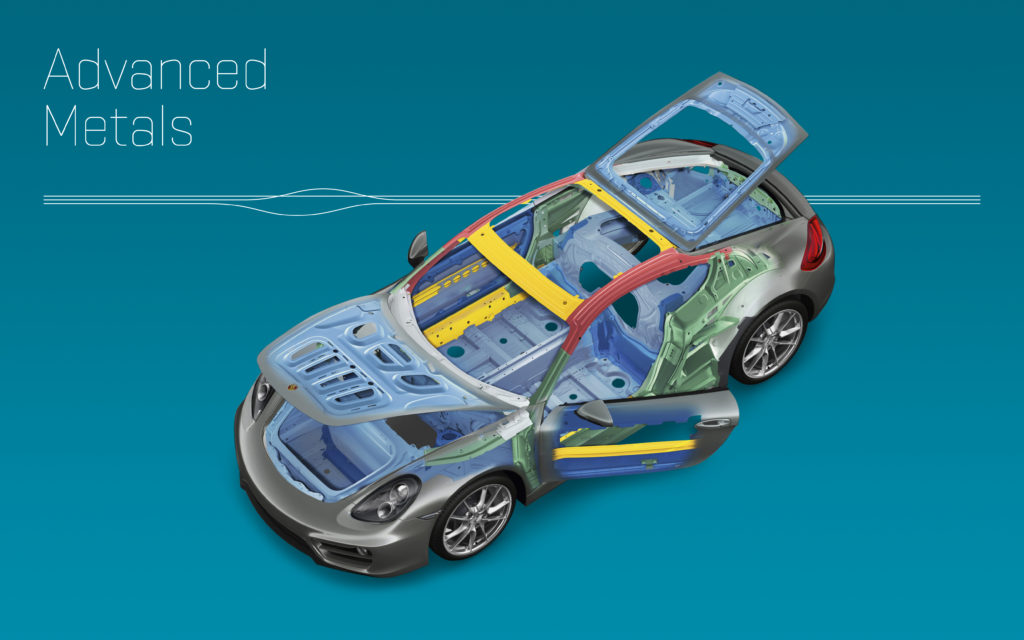

The research in the cluster Advanced Metals includes the three key stages for the application of metals: processing, microstructure formation and properties and performance.

The focus is on identifying and understanding the physical fundamentals of the processes, aiming to apply the basic understanding to further development of processes and materials in industrial applications.

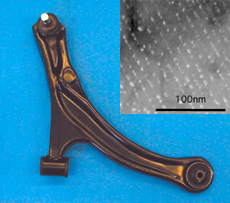

Resource-Efficient NANO-Steels

The international resource panel of the United Nations Environmental Program and the European Commission proclaim ‘resource efficiency’ necessary to sustain a sufficient supply of resources to a growing world population.

Steel consumption and CO2 emissions can be reduced simultaneously with NANOsteels that are being developed for lightweight automotive applications and high-rise buildings for fire-resistance. The drawback of NANO-steels is that they rely on considerable

micro-alloying additions that form the essential nanometer-sized precipitates.

The project aims at obtaining fundamental insight into the role of individual chemical elements on the precipitation and phase transformation kinetics, which is deemed essential for the development of NANO-steels with reduced amounts of alloying elements

without compromising properties.

Thermo-Mechanical Fatigue in Cast Iron – Specifically Occurring in Truck Engines

The objective of the program is to unravel the physical complexity governing initiation and development of damage and failure in complex and dynamically changing microstructures in metals.

The scientific aim of this project is to elucidate the physical mechanism of failure, developing under repetitive impact loading, by identifying relations between damaged initiation and propagation and microstructural features at the nano-scale (interfaces, precipitates) and the micro-scale (grain dimensions and morphology, crystallographic orientations).

Contact Details Cluster Advanced Metals

For more information about our Advanced Metals Cluster, please contact Viktoria Savran.