M2i’s Multi Scale Modelling of Mechanical Behaviour Cluster focuses on the fundamental understanding of various problems in materials engineering at different length scales, which emerge from the physics and the mechanics of the underlying material or multi-material microstructure.

The main challenge within this program is the accurate prediction of mechanical properties of materials (i.e. structural materials) or small-scale components with complex microstructures, in view of their application in microsystems (i.e. functional materials).

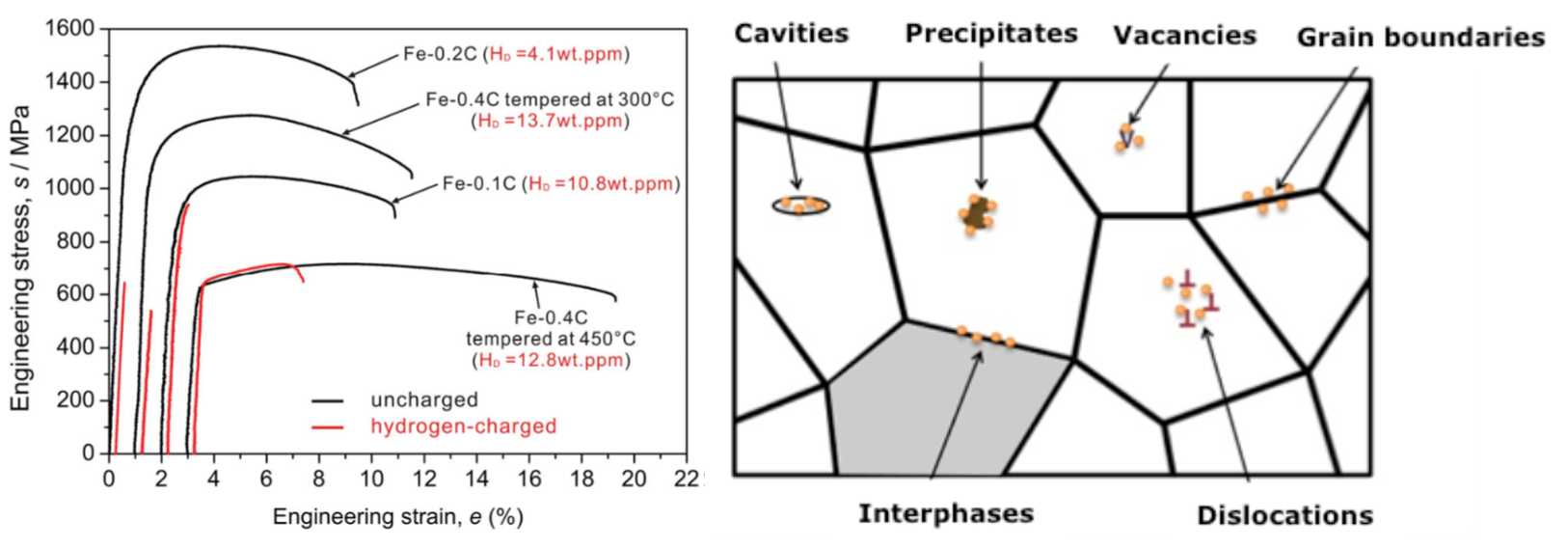

Design hydrogen-resistant alloys through novel multi-scale modelling and experimentation

Hydrogen embrittlement (HE) is an outstanding problem in the mechanics of structural metals. It results in the deterioration of mechanical properties, such as strength and deformability, when hydrogen is present in metals or its environment (water, acids, …). Severe loss of strength and deformability can already occur at almost negligible hydrogen concentrations (order of 1 ppm). Solutions to this problem directly benefit the upcoming hydrogen economy by prevention of failure of large-scale structures such as fuel pipelines. To date, despite many of research efforts, the fundamental origin of HE is largely unknown for all metals. This project aims at such paradigm shift by solving HE in multi-phase steels. The focus is on steels, because they are among the most important structural metals. Experimental characterization provides essential information about hydrogen degradation and segregation at important microstructural features in steels, as well as key validation of the new multi-scale modeling framework. The multi-scale modeling approach based on Molecular Dynamics and crystal plasticity modeling will connect atomistic information with microstructural behaviour of multi-phase steels in presence of hydrogen. This knowledge enables design of new steels that are HE resistant.

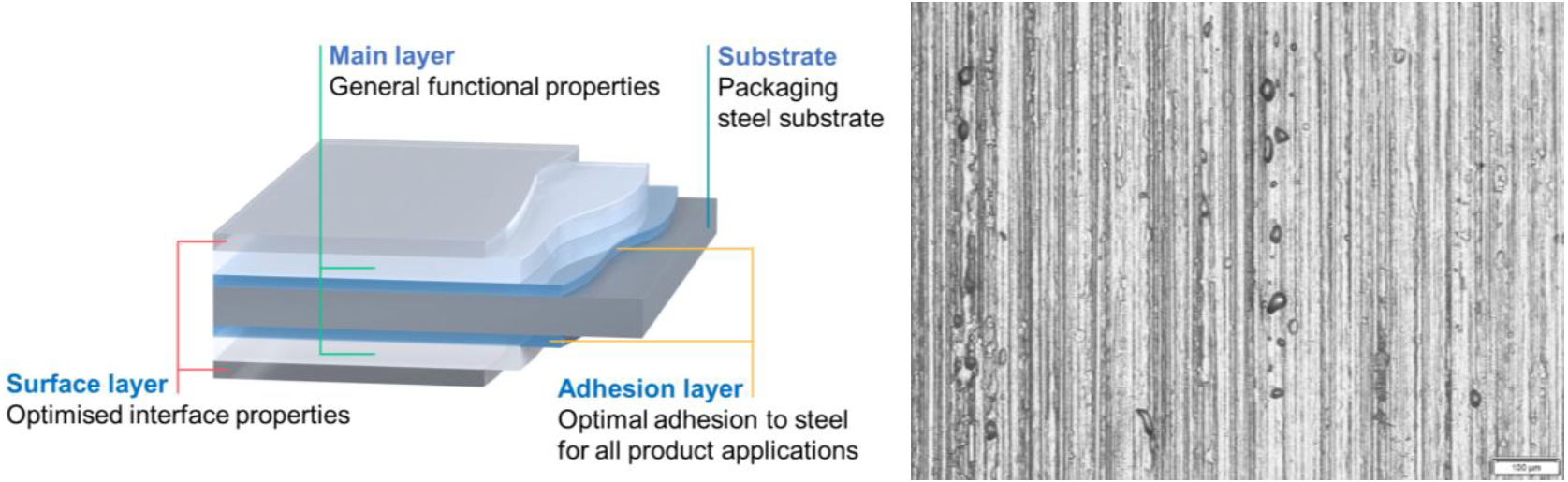

Unravelling air entrapment during polymer thin film lamination

Packaging steels are nowadays widely used in the beverage and food industry. These steel sheets are covered with a coating for preserving the quality of the content, preventing corrosion and enabling printability at the outside. Such coatings need to comply with strict health and environmental regulations. For this reason, thermoplastic polymers are nowadays used, which are laminated and bonded on the packaging steel. This industrial lamination process needs to handle large volumes at large speeds, and this is where a critical problem emerges. At high line speeds, air bubbles get entrapped between the polymer coating and the steel substrate, which severely affect the quality of the final product. The physics governing this air entrapment process is poorly understood, and the relation with overall process parameters is critical in controlling this. This project will address this problem, using a two-scale modelling strategy, complemented by some experiments. The coarse scale is modelled to establish the link between processing parameters (line speed, roll pressure, temperature, …) and the actual loading conditions in the lamination nip where the film is bonded. The fine scale model descends to the level of the roughness asperities of the steel sheet, where the plastic flow of the film at high temperature into the roughness valleys is explicitly studied.

More information

For more information about M2i’s Multi Scale Modelling of Mechanical Behaviour Cluster, please contact Jeroen van Beeck.