Project Description

Key information

EU funding: € 7,91 Million

Total budget: € 9,75 Million

Duration: 48 months [March 2020 – Feb 2024]

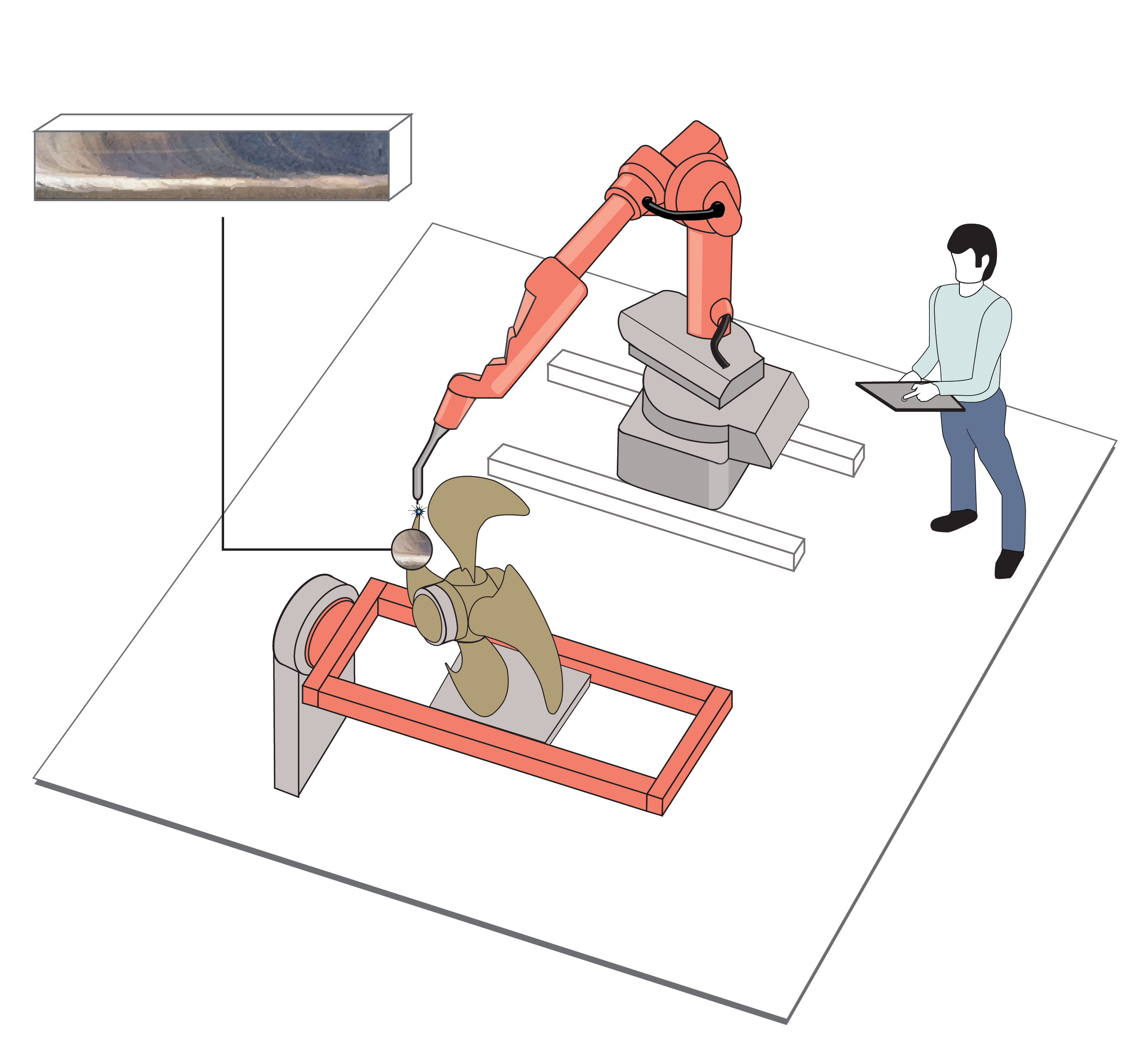

Background: Grade2XL is a joint development programme aligning partners along the value chain to foster the rapid development of WAAM materials and process. Grade2XL will deliver multi-material products of superior quality and performance. The high printing rate of WAAM, combined with the ability to control material properties down to the nanoscale, will enable building strong and durable engineering structures.

The Grade2XL project, funded by the programme Horizon 2020, will demonstrate the potential of multi-material wire arc additive manufacturing (WAAM) for large structures ~1 to >10 m length. Grade2XL will strengthen Europe’s capacity to drive manufacturing innovation globally and withstand growing competition from Asia.

M2i is leading the Grade2XL consortium and has been carrying out the following tasks:

- Project initiation: proposal coordination and writing, consortium building

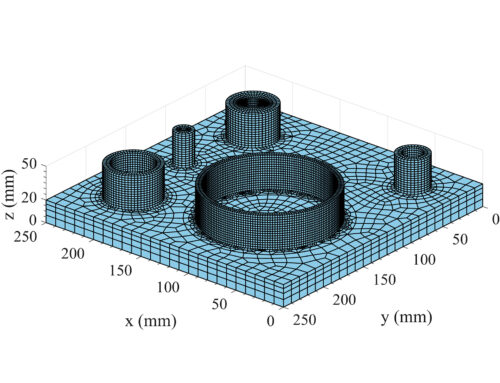

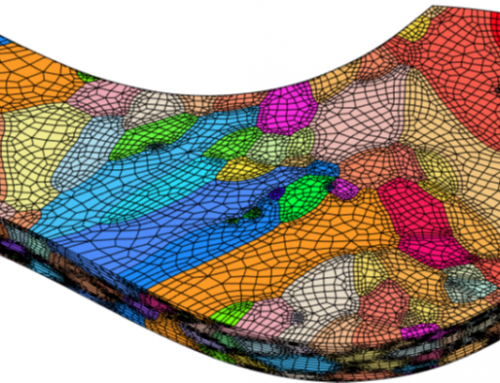

- (WP 1 Functional grading) Topology optimisation: Design tool for graded structures with minimum distortions

- (WP 7 Dissemination and exploitation): Generic communication and support in organising a WAAM Roadshow

- (WP 8 Project management): Main contact point with the European Commission, day-to-day management

Project Partners:

- Stichting Materials Innovation Institute (M2i), The Netherlands – Lead Partner

- Rotterdam Additive Manufacturing Fieldlab (RAMLAB), The Netherlands

- Gent University, Belgium

- Delft University of Technology, The Netherlands

- Commissariat à l’énergie atomique et aux (CEA), France

- Technical Univerrsity of Denmark, Denmark

- voestalpine Böhler Welding, Germany

- Valk Welding, The Netherlands

- Air Products, Belgium

- Lincoln Electric Europe, The Netherlands

- Politechnika Wrocławska, Poland

- Naval Group, France

- Gorenje Orodjarna, Slovenia

- Energie de France, France

- Arrk Shapers, France

- MAN Energy Solutions, Denmark

- Ucosan (Villeroy&Boch), The Netherlands

- GKN Aerospace Services Ltd, United Kingdom

- Kuźnia Jawor S.A., Poland

- Bureau Veritas, France

- Pôle EMC2, France

Ambition:

Grade2XL will deliver a multi-material, high throughput WAAM system, removing the technological barriers that hinder the application of WAAM, on three levels:

- Material level: functionally graded (multi)materials will be achieved by controlling the two main factors governing the material properties: the chemical composition and the thermal.

- Process level: high WAAM productivity will be achieved using multiple wire deposition systems. The productivity will increase from typically 2 kg/h to 5 kg/h, which can double when a dual robot configuration is used. In-line contactless inspection will ensure first time right quality and facilitate qualification.

- Life cycle or system level: challenging applications will demonstrate the lifecycle benefits of WAAM multi-material devices and in-line process control.

News

Grade2XL final movie released

The final movie of Grade2XL is released. Watch it now and see all the amazing project results highlighted in the movie!

The Grade2XL project partners meet in Denmark: final meeting

On 27 and 28 August 2024, MAN Energy Solutions hosted in Frederikshavn (Denmark) a 2-day meeting with the Grade2XL partners for the project review sessions and an industrial visit of

Grade2XL Shines at the prestigious Institute of Welding conference (IIW2024) in Rhodes, Greece

Between 7-12th July, the historic and picturesque island of Rhodes, Greece, hosted the 77th Annual Assembly of the International Institute of Welding (IIW), a major event in the global welding

Final Event Grade2XL on 11 July 2024 during the IIW2024

The final event for the Grade2XL project will be held during IIW Annual Assembly and International Conference (7-12 July, Rhodes, Greece). On 11 July Grade2XL will have its own dedicated

Next Grade2XL webinar: “Engineering the Future” on 21 June

The last Grade2XL webinar will be on Friday 21 June at 13:00, this time the topic is “Engineering the Future: Harnessing Topology Optimization and Wire Arc Additive Manufacturing for Advanced Design

Next Grade2XL webinar: “Non-destructive testing and monitoring techniques for AM metallic parts” on 12 April

The Grade2XL webinar will be on Friday 12 April at 13:00, this time the topic is “Non-destructive testing and monitoring techniques for additive manufactured metallic parts”. In this Grade2XL webinar the