Project Description

Key information

Project in the Spotlight: E17002 (2S03-051 Qualify)

Market: Maritime Industry

Written by: Franz Bormann

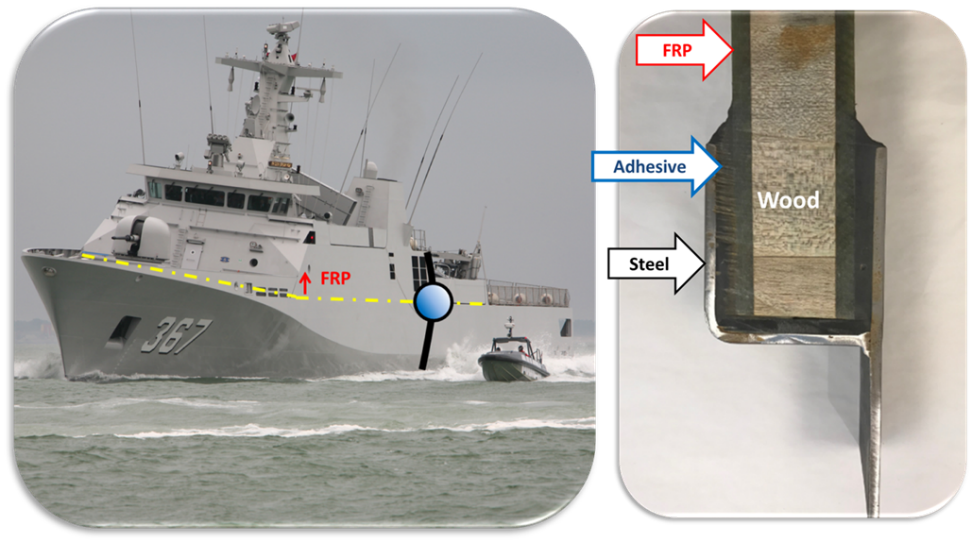

In the past years, the maritime industry has been facing an increasing demand for decarbonisation and sustainability. One of the conventional routes to achieve a substantial reduction in carbon emissions is to lower fuel consumption. This can be achieved through lightweight ship designs. Given that primary structures of vessels are commonly based on steel designs, the shipbuilding industry has been exploring modern, lightweight alternatives. One remarkable option is the category of adhesively bonded hybrid (composite-steel) joints, which are capable of withstanding the harsh environmental and operational conditions they are facing on open sea, without compromising safety. Yet, given the relative novelty of such joints in maritime applications (as compared to the conventional steel design), it is no surprise that certification guidelines of such hybrid joints have been missing – until now.

Project objectives and outcomes

Funded by the European Interreg 2 Seas programme, the QUALIFY project brought together an international team of experts from academia, industry, and classification societies. The consortium worked in a multi-disciplinary effort towards the elimination of major technical barriers against the widespread application of hybrid joints in the maritime industry. Specific main goals were the formulation of a regulatory framework and the development of reliable inspection and maintenance technologies to enable the application of hybrid joints for primary structures in future ship designs.

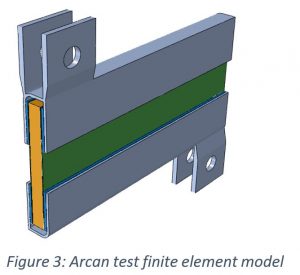

Subject of detailed investigations were two representative joint designs provided by the DAMEN Group and BAE Systems. Simulations on the ship scale were performed to extract critical stress states which the joint is likely to experience under extreme operational conditions. With this information Arcan test samples were manufactured to replicate such a stress state. A deliberate experimental route was then followed using the specific Arcan samples as well as tensile samples for a detailed assessment of the joint strength. Static and fatigue experiments of both non-aged and aged samples created a solid foundation for a thorough certification strategy.

Subject of detailed investigations were two representative joint designs provided by the DAMEN Group and BAE Systems. Simulations on the ship scale were performed to extract critical stress states which the joint is likely to experience under extreme operational conditions. With this information Arcan test samples were manufactured to replicate such a stress state. A deliberate experimental route was then followed using the specific Arcan samples as well as tensile samples for a detailed assessment of the joint strength. Static and fatigue experiments of both non-aged and aged samples created a solid foundation for a thorough certification strategy.

On a parallel track, dedicated finite element (FE) simulations were performed by our simulation team in a three-step approach. First, the individual material and interface models for each of the relevant joint components were calibrated based on experiments at the material and coupon level. Primary focus here was the ductility of the adhesive, and the interface fracture properties of the bonded interfaces (steel/adhesive and composite/adhesive). Secondly, with the successfully calibrated models, the tensile and Arcan tests were then virtually replicated. The simulation results granted a rich insight into the specific failure mechanisms, demonstrating its great complementary character with regard to the experiments and the certification. In a third step, we advanced from the experimental comparison and modelled a structural subcomponent to assess the influence of pre-existing damage on the joint under operational conditions. The results showed that even under severe damage assumptions the joint is still capable of withstanding extreme loads.

and interface models for each of the relevant joint components were calibrated based on experiments at the material and coupon level. Primary focus here was the ductility of the adhesive, and the interface fracture properties of the bonded interfaces (steel/adhesive and composite/adhesive). Secondly, with the successfully calibrated models, the tensile and Arcan tests were then virtually replicated. The simulation results granted a rich insight into the specific failure mechanisms, demonstrating its great complementary character with regard to the experiments and the certification. In a third step, we advanced from the experimental comparison and modelled a structural subcomponent to assess the influence of pre-existing damage on the joint under operational conditions. The results showed that even under severe damage assumptions the joint is still capable of withstanding extreme loads.

The third pillar of the project was dedicated towards creating an efficient inspection and monitoring protocol. Using fibre optic sensing technology, a methodology for the in-situ monitoring of adhesively bonded hybrid joints has been developed. It has been demonstrated that the onset of damage can be detected, the damage hotspots located, and even the type of damage identified, including a quantification of its severity.

The overall results of the project were exceptional. The strong long-term performance of hybrid adhesive joints has been explicitly proven, an inspection and monitoring protocol has been drafted, and a guideline document for the entire qualification process of composite-to-steel adhesively bonded joints has been written (see: Guidelines for the qualification of adhesively bonded hybrid structures in primary structures for marine applications). With this project the groundwork has been laid for the application of hybrid joints in primary structures. It is expected that this change will grant the maritime industry a reduced fuel consumption of up to 7% – a big step towards increased sustainability which will also motivate other sectors to gradually orient their designs towards metal-composite structures.

The presentations given at the project final event can be viewed here.

This research was carried out within the project “QUAILIFY – Enabling Qualification of Hybrid Joints for Lightweight and Safe Maritime Transport”, co-funded by the INTERREG 2SeasMers Zeeën programme http://www.interreg2seas.eu/qualify

This research was carried out within the project “QUAILIFY – Enabling Qualification of Hybrid Joints for Lightweight and Safe Maritime Transport”, co-funded by the INTERREG 2SeasMers Zeeën programme http://www.interreg2seas.eu/qualify

Cedric Verhaeghe (Damen Naval, The Netherlands)

Cedric Verhaeghe (Damen Naval, The Netherlands)

In the Qualify project we were able to overcome the main hurdles that were holding back the application of our steel to composite joint. Working together with knowledge institutes such as M2i greatly increased our understanding of the behavior of the joint during its 30 years at sea. This in turn helped us to convincingly predict and validate the performance of the joint over time.

Linda Starink (LR, United Kingdom)

The Qualify project gave us the chance to collaborate with both industrial and academic partners, giving us the opportunity to look at ways to de-risk novel adhesive hybrid joints. The range of knowledge and experience brought together by M2i, has helped us, as a team, to create a framework that gives clear guidelines to achieving approval of hybrid joints and a consistent testing regime that will help to assess and reduce the risks associated with future novel adhesive joint concepts.

Wim de Waele (Ghent University, Belgium)

Wim de Waele (Ghent University, Belgium)

We are proud to have contributed to the Qualify project with test methods for accelerated ageing and integrity assessment of steel to composite joints. The professional coordination by M2i ensured an intense collaboration and knowledge sharing between knowledge institutes, classification societies and industry. Being part of this multi-disciplinary consortium has been an enriching experience for our research team. The guidelines developed by the consortium will allow the introduction of multimaterial adhesive joints into primary marine structures.