Project Description

Key information

Program title: Transforming carbon-rich industrial waste gases of metallurgical plants into valuable products

Project in the Spotlight: C19017

Funding: NWO PPP Fund 2019 – IPP

Run time: September 2020 – December 2024

Market: Chemical Technology, Circularity and Material Production

Written by M2i Program Manager: Jeroen van Beeck

Research Program

The metallurgical industry, including steel producers such as Tata Steel, is one of the largest CO2 emitting industries. The TRANSCRIPT research program aims to develop the necessary catalysts and related technology to convert the works arising gases (WAGs) from the production process into useful base chemicals using CO2 capture, utilization, and storage (CCUS) technologies. Examples of base chemicals are methanol and higher alcohols as well as methane and higher hydrocarbons, including aromatics. The main goal of the TRANSCRIPT research program is to establish novel thermo- and electrocatalytic processes that can convert CO2 emissions from steel manufacturing into high-value chemicals. The program consists of five PhD students and two PostDoctoral researchers.

Research strategy

The program studies several possible catalyst materials for promoting the required conversion of CO2 to valuable chemicals. The catalysts for thermo- and electrocatalytic CO2 conversion are studied under different operational conditions to determine the best catalyst particle size, composition, and related operational conditions for specific reaction product formation. Advanced analytical tools, such as multi-wavelength Raman spectroscopy, X-ray spectroscopy, and more, are used to investigate the catalysts under realistic reaction conditions.

Main results

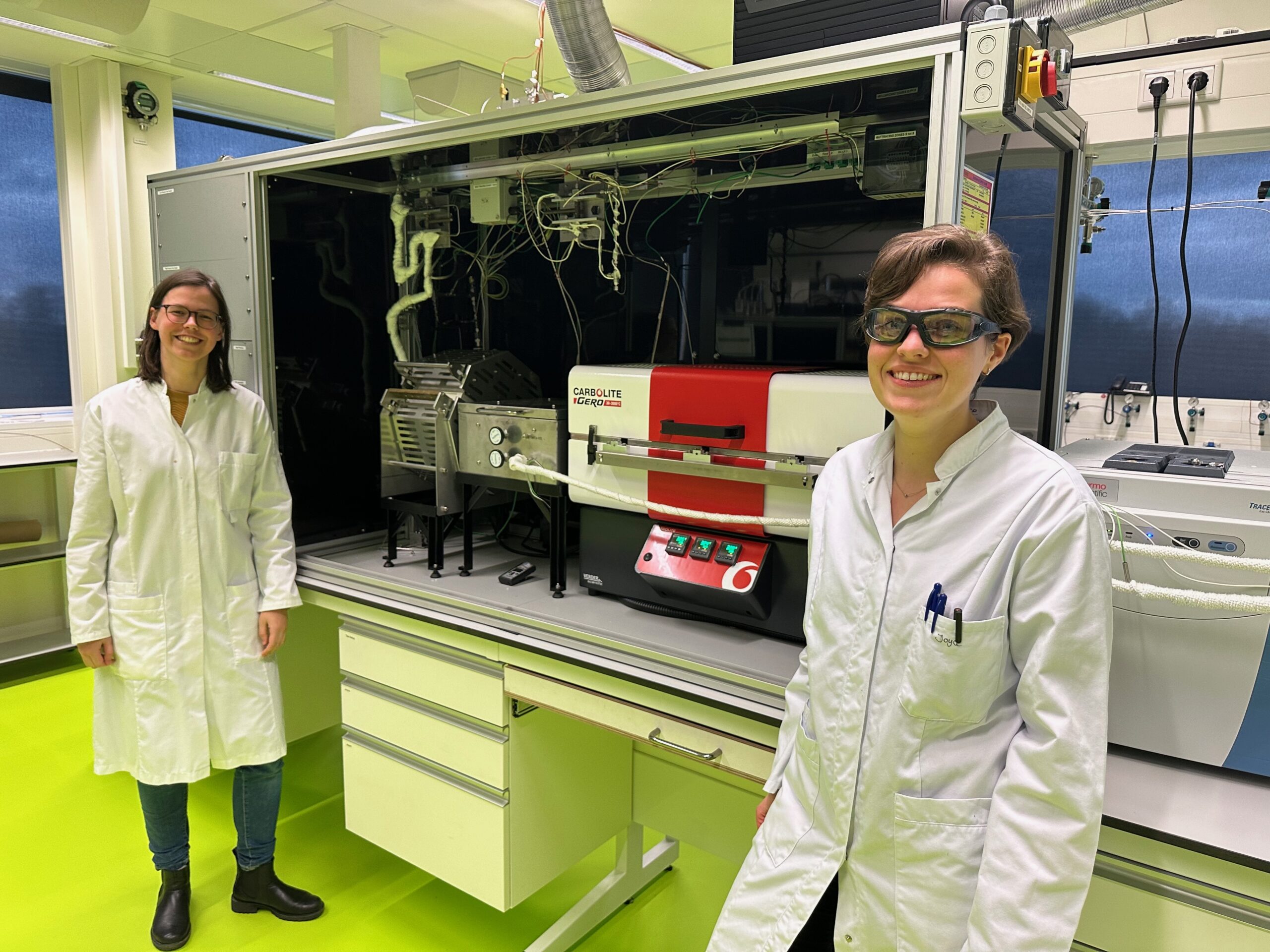

At Utrecht University, the research team investigates the thermochemical catalytic process options. The team has developed a novel two-stage reactor setup to study the catalytic conversion processes. Together with several spectroscopic measurement techniques, this setup allows them to investigate how different gases and compositions react. Their results show the potency of various catalysts for efficient and effective thermochemical conversion of CO2, thereby forming first methane, which is subsequently transformed into aromatics.

Figure 1 – Two-stage reactor developed at Utrecht University with PhD researchers Angela Melchert (left) and Joyce Kromwijk (right).

Figure 1 – Two-stage reactor developed at Utrecht University with PhD researchers Angela Melchert (left) and Joyce Kromwijk (right).

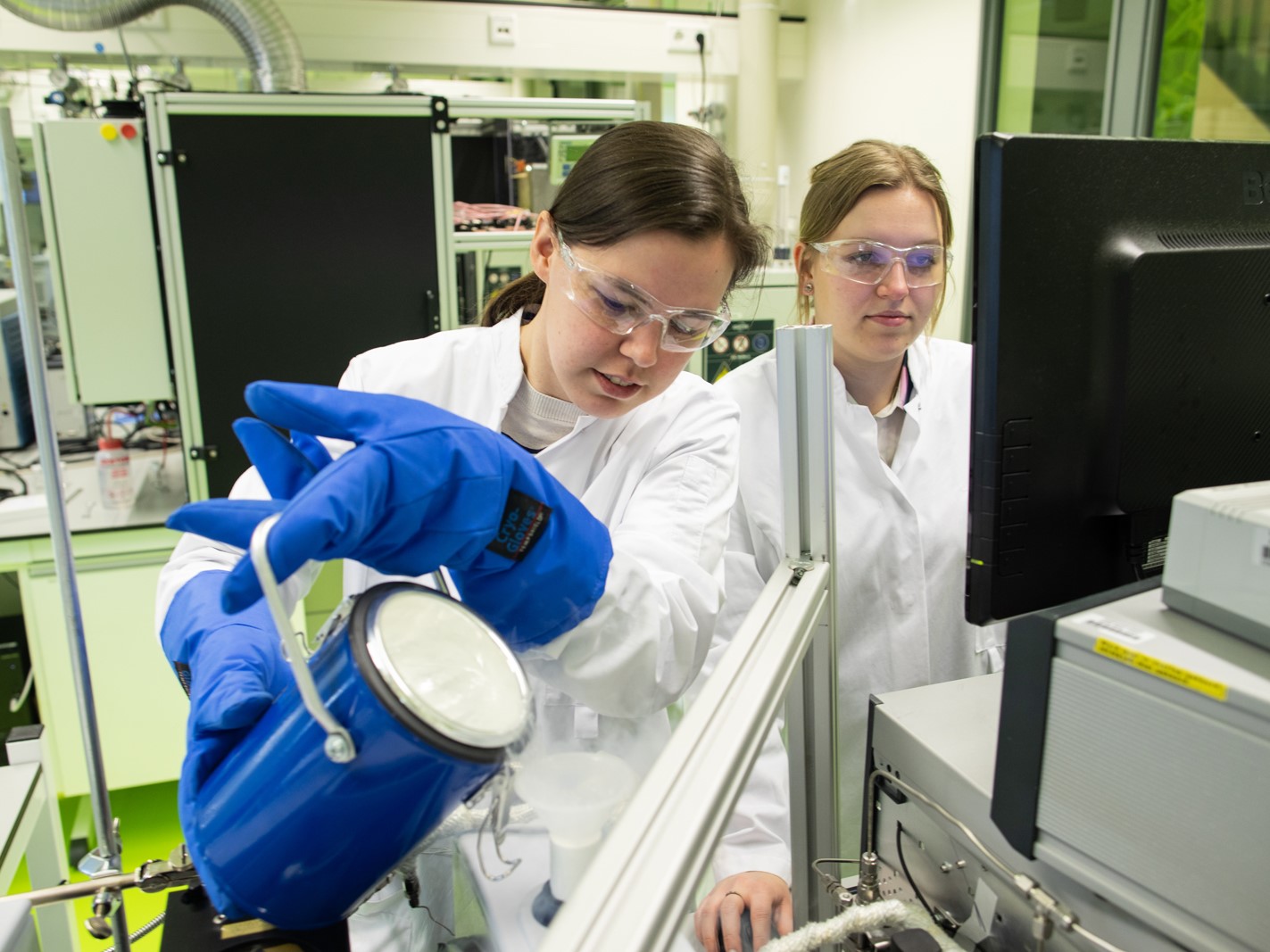

Complementing the Utrecht team, at Leiden University, the research team studies electrochemical catalysis. Their results show that the efficiency of reducing CO2 depends strongly on the process conditions, especially temperature. New reaction paths for C-C bond formation were identified, and how they depend on temperature and catalyst used. The group developed a high high-pressure electrochemical reactor which allows studying copper electrocatalysts at high temperature, showing substantially different reaction products compared to low temperature. Their results thus provide useful insights into how to make the electrochemical conversion of CO2 more efficient and practical. Several synergistic collaborations between Utrecht and Leiden were started, with the innovative deployment of the luminescent thermometry developed in Utrecht applied to the electrochemical systems studied in Leiden, being the most eye-catching.

Future direction

The TRANSCRIPT research program has the potential to make significant contributions towards reducing CO2 emissions in the steel manufacturing industry while also producing high-value chemicals. The future direction of the program will likely involve further optimization of the catalysts, process conditions, and related technologies, as well as scaling up involved technologies.

Thus, the TRANSCRIPT research program is an innovative effort that showcases the potential of combining CCUS technologies with steel production processes to address one of the most significant challenges facing society today. By developing novel thermo- and electrocatalytic processes for converting CO2 emissions into high-value chemicals, Tata Steel is demonstrating its commitment to sustainability and reducing the environmental impact of the steel industry.

The consortium

The TRANSCRIPT research program brings together two groups with a track record in thermochemical (Utrecht University) and electrochemical (Leiden University) CO2 conversion processes, and a major industrial partner interested in CO2 valorization (Tata Steel). By combining their expertise, the program develops new catalysts and related technologies that can convert CO2 emissions from steel manufacturing into high-value chemicals, while also reducing CO2 emissions. During the program, a strong collaboration was developed and fostered between the different researchers.

Jan van der Stel, Tata Steel Nederland

Jan van der Stel, Tata Steel Nederland

“Tata Steel has a clear strategy to strongly reduce the carbon footprint of our steel production process. While our direct focus is on avoidance of emissions through application of hydrogen, electrification and increased scrap usage, the TRANSCRIPT program is a great platform for understanding other potential solutions to reducing this footprint indirectly, e.g. via conversion of the emissions to valuable chemicals after capture.”

Angela Melcherts, Utrecht University

“The past years we worked to build a two-stage reactor system for the reaction of CO2 into aromatics, via methane as intermediate. By taking the waste offgas from the metallurgical industry, containing CO2, CO, and steam, we try to develop a catalytic system that is versatile and robust towards the presence of various impurities. By using multiple spectroscopic techniques, such as UV-Vis and Luminesence thermometry, we can visualize the effects of these impurities on our catalytic process. This way we try to fundamentally understand our catalyst, by still keeping it in the context of real-life challenges.”

Rafael Vos, Leiden University

Rafael Vos, Leiden University

“With the high pressure, high temperature electrochemical cell we developed in this project, we are able to study electrochemical CO2 reduction at more industrial relevant conditions and get fundamental knowledge about the effect of temperature and pressure. Moreover, we now acquired the tools to bridge the gap between thermo- and electrocatalysis and gain understanding about the differences in catalytic activity.”