The project Smart*Light 2.0 aims to develop a ‘tabletop synchrotron’—a reliable and optimized instrument for specific X-ray analysis techniques, with a focus on fluorescence, diffraction, scattering, spectroscopy, and tomography. These techniques enable researchers to investigate the elemental composition, atomic structure, nanostructure, chemical composition, and 3D structure on a sub-millimeter scale—a critical aspect of material

Ductile damage and crack propagation

M2i2020-11-26T14:15:58+01:00Objectives: Prediction of shape during metal blanking and cutting processes. M2i FEA simulation work: Development and implementation of 2D non-local damage and crack propagation model using MSC.MARC and in-house software (2005) Development and implementation of 3D non-local damage and crack propagation model using MSC.MARC and in-house software (2010) Integration of 2D and 3D models

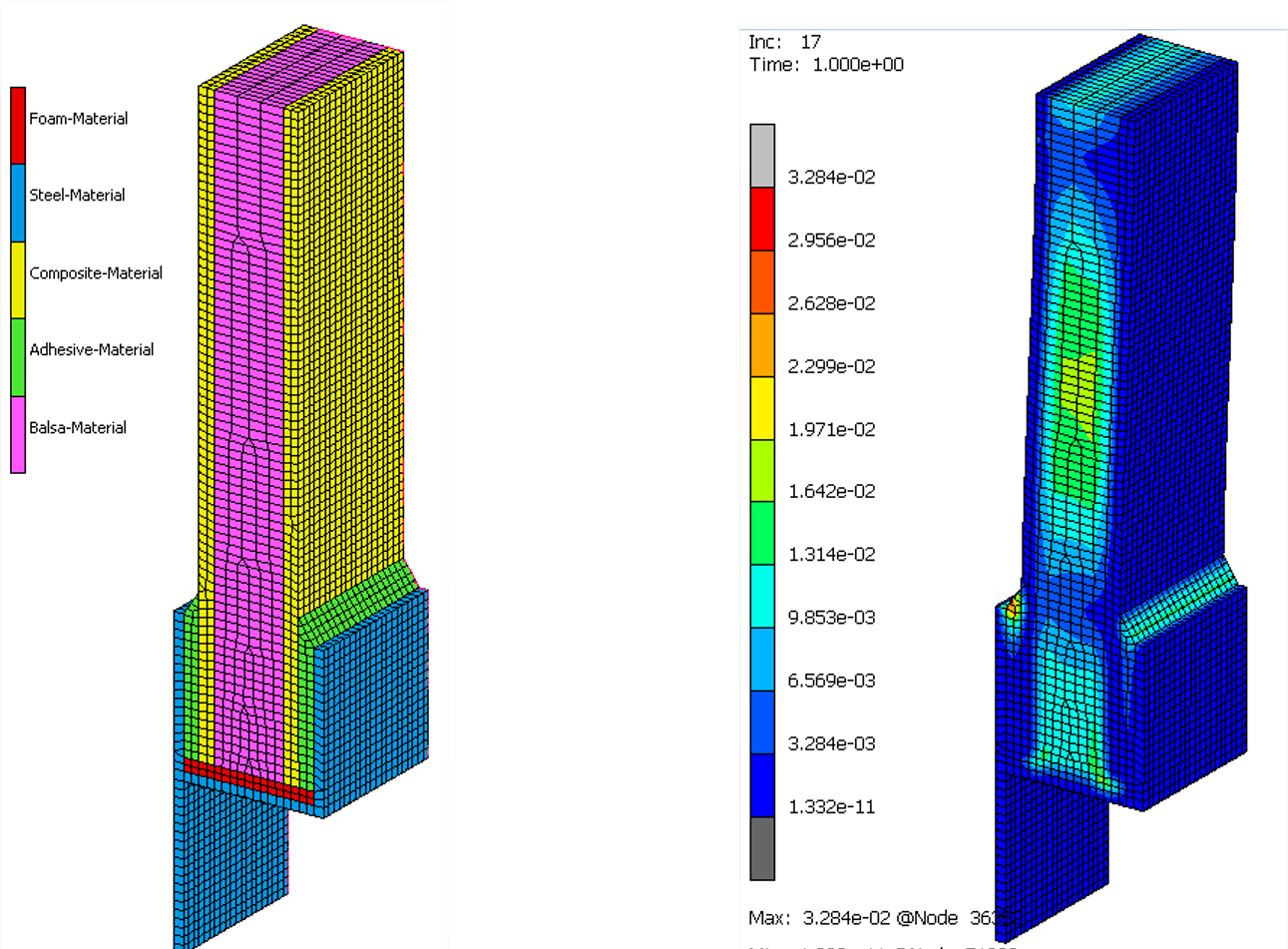

Failure prediction of adhesive hybrid-joint (composite-steel) under mechanical loading

M2i2020-11-26T14:07:36+01:00Objectives: Evaluate the long term structural performance of the adhesively bonded hybrid joint under operational and environmental conditions; Develop a reliable inspection and maintenance methodology for adhesively bonded hybrid joints; Develop a procedure (Guidelines) for the qualification of adhesively bonded hybrid joints in primary structures in marine applications.. M2i FEA simulation work:

Topology optimization of 3D printed implants and prosthesis

M2i2020-11-26T14:15:27+01:00Objectives: Integration of diagnosis, design and manufacturing of 3DP medical devices in a software platform. Personalized medical devices (prostheses, implants, orthoses) M2i FEA simulation work: Develop robust and easy to use FEA models of 3D printed model of implants and orthotics Topology optimization of designs Industrial Benefits: Reduce the complexity of advanced

Implementation of VMAP wrapper to transfer data between different FEA-CAE software

M2i2020-11-26T14:08:50+01:00Objectives: Enhance interoperability in virtual engineering workflows by developing a vendor-neutral standard for CAE data storage. Implementation in several software tools, and validation with a number of industrial use cases. M2i FEA simulation work: One of the project use cases is the manufacturing of a Philips shaver. It involves the injection moulding of a

Grade2XL – Functionally Graded Materials for Extra-Large Parts

Anniek Enserink2024-04-08T12:45:12+02:00Key information EU funding: € 7,91 Million Total budget: € 9,75 Million Duration: 48 months [March 2020 - Feb 2024] Background: Grade2XL is a joint development programme aligning partners along the value chain to foster the rapid development of WAAM materials and process. Grade2XL will deliver multi-material products of superior

SUNRISE – Solar Energy for a Circular Economy

Marcella Klouwens2024-04-04T14:24:57+02:00Key information: EU funding: € 1 Million Total budget: € 1.08 Million Duration: 12 months [March 2019 - February 2020] Background: M2i will ensure the management of the SUNRISE CSA, on behalf of the coordinator Leiden University, Prof. Huub de Groot. CSAs are Coordination and Support actions meant to streamline the efforts

3DMed – Development and streamlined integration of 3D printing technologies to enable advanced medical treatment and its widespread application

Anniek Enserink2024-04-04T16:47:50+02:00Key information EU funding: € 4.10 Million Total budget: € 6.84 Million Duration: 44 months [October 2018 – May 2022] Background: The project 3DMed was approved on the 12th July 2018 by Monitoring Committee of INTERREG 2Seas programme. M2i has played a key role in this success, by steering the application on behalf of

VMAP – Virtual Material Modelling in Manufacturing

M2i2024-04-04T16:44:59+02:00Key Information: ITEA 3 Call 3 Total budget: € 15,884 k€ Duration: 48 months [Sep 2017 - Aug 2020] The challenge: The lack of software standards in virtual engineering workflows and incompatible interfaces for the transfer of virtual material information not only cause additional costs and complex manual adaptation but also lead to

Smart*Light: Transboundary research for highly innovative X-ray solutions

Anniek Enserink2024-04-04T16:41:47+02:00The program Smart*light was funded by Interreg Vlaanderen-Nederland. The research project Smart*Light develops a compact and portable X-ray source with variable wavelength, a ‘tabletop synchrotron’. A consortium of 12 organizations in The Netherlands and Flandres receives a subsidy of 2,85M Euros from the European Regional Development Fund (Interreg Flandres – The Netherlands). Smart*Light will